Monday, August 15, 2005

The Work Vacation Begins

But right now I'm organizing. I'm setting out all the things we intend to do. After mucking around with the welder a bit, we agreed--neither of us feels confident about welding on a new coupler. So, we are going to reassemble the hitch, leaving an access panel so that Rick can pull the wiring harness when we take it to the shop to replace the coupler.

That makes the rest of the hitch reconstruction easier. We will replace the sway bar clamps (for some crazy reason one is further forward than the other). Other targets for the week--replace the flooring, redo the plumbing, rebuild the gas bottle carrier and weld in another reinforcement bar into the frame. That should leave us in a place where most of the rest of the work will be in the happy-to-glad category. Oh, yeah--we have a beautiful new fiberglass skylight (from our good friend Steve at airstreamdreams.com), a door handle to fit in, and another Fantastic Vent to install. Nothing for a week, right?

We are in agreement--we gotta get things back to a point where we can get back on the road and really enjoy this thing!

Monday, July 18, 2005

Getting Back to Work

Yesterday, the muggiest day in a very long time, I went back into the shell and went back to working on woodwork. A hour later, I was covered head to toe in dampness. I don't think it was perspiration, since it was early and cool. All my dry clothes were just a wick for the humidity. I also think, but cannot verify, that the humidity impaired the refinishing chemicals--it all seemed to take longer.

Earlier in the week, Rick ordered a new power jack. We've been wrestling with this, but it's a little luxury I think Rick will enjoy. Meanwhile, we are still figuring out how much we are going to replace on the toungue. One thing we did figure out--the sway bar clamps are not set symetrically on the trailer--so that's something we'll definitely replace. We'd like to also replace the receiver, since the old one is a little sticky. However, the old one is also very well attached to the frame--so cutting it off may end up becoming too much for us to accomplish.

Doing this is holding us back from finalizing the electric. Why? Because the harness has to pass through the frame--where we plan to weld. Rick is considering putting in a little access panel on the inside, which would allow him to pass the wiring through at a later date. Clever, huh?

Tuesday, June 21, 2005

Airstream Roadshow!

- Try to get early entry tix. The experts are all on a race to claim airtime, so filming slots go fast.

- Avoid bringing paintings or glass items, unless you are convinced they are really valuable and willing to stand in line forever.

- You will not have a long wait if you have an ancient antiquity--however, Roadshow rules forbid coins. The antiquity guy needs more business!

- The most familiar experts end up being the friendliest and most helpful. The dirt I got is that the newbies tend to get nervous about finding items that will get them airtime, not getting customers or supporters.

- When I mentioned our trailer to the experts, most gave very envious sighs. Airstreams are really desireable to dealers, who have to tote their stuff around the country and have a sense of style.

- Going to Antiques Roadshow is a blast (and we loved Noel Barrett), even if you don't make TV!

Thursday, June 16, 2005

Airstream Physics

1. Things fit better in an Airstream than any other space...always

2. Outside the Airstream, tough, well built cabinets become rickety and delicate.

3. Things appear smaller in an Airstream, unless you have to repair them.

Well, by clearing out a closet, we were able to get a nice, neat place for most of our tool boxes. We still face moving all of the other stuff in the guest bedroom--I think it's going to end up making our basement pretty much a warren.

Meanwhile, there is the continous campaign for acquisition management. We received an order yesterday from Airstream Dreams. As I expected, the skylight cover looks nothing like the previous DIY job--and we are especially happy that it has a sealed in metal plate for riveting it in. As I suspected, the new bulb seal (what I had previously called the windows' "mystery gasket" is a whole lot more durable than the foam weatherstripping I had used when working on the windows. Slowly, I'm going to start replacing these. The package rounded out with a pair of tee shirts and (eeek) a tub of coarse aluminum polish. Someday soon, I will start down that evil path too...Another package brought a new can of Por-15's Stirling Silver and Marine Clean. Now, if Rick gets a new hitch and I track down more Fornby's, we'll have most of our supplies for the forseeable work (except plumbing, which seems to always be a figure as we go case).

But meanwhile, I'm off this weekend to New England. Highlight of my trip will be going to The Antiques Roadshow in Providence, RI! Sadly, they don't value vintage trailers on the Roadshow (nor, according to the instructions on my tickets, vehicles of any kind). Not that the Toaster is ready for the Keno brothers--we still have a lot of work to do. Rick's going to study while I'm gone, since he has final exams all next week. Unless I can find a night off for trailer work, I probably won't be posting much news until after June 26. Then we're bringing on the heat and getting cranking (as we face the summer heat)!

Sunday, June 12, 2005

Ode to Working on the Trailer When it’s 90° with 100% Humidity

Restoring an Airstream

Isn’t always a pleasant dream,

It always seems that something unexpected bites me in the butt,

Leaving me irritated and occasionally in sobs.

I know if I get myself out of this darn rut,

I may finish up all these bleep bleep bleeping darn jobs

Rotozips and sawzalls

Leave me dog tired so I know well

A dream trailer is hard won when sauna conditions put me in a snit.

Yet, when I really want to unwind,

When summer’s heat leaves me truly unfit,

I wonder is it really the weather or do I just have beer on my mind?

Refinish my brain, please

Remove that adhesive in two applications! Hahahaha! That darn wall took three hours of endurance scraping and endless reapplications! They really used fantastic glue, back in the day. Tough part is, it is a truly purgatorial task to remove it. But eventually, persuasive treatment with steel wool prevailed. Then I managed to eek out two cabinets of refinishing before running out of Fornby’s furniture refinisher. Now I have to find more of that stuff—they don’t sell it at Home Depot any more, so I’ll be shopping hardware stores this weekend. Still, I think I’ll be able to finish the rest of the woodworking in fairly fast fashion, though I know how this blog will start to sound:

Day 1: detailed description of refinishing the furniture

Day 2: discussion of some of the discoveries of refinishing the furniture

Day 3: rant about frustrating elements of refinishing the furniture

Day 4: poetry about refinishing furniture

Day 5: hey, I’m working on refinishing the furniture, but doing this darn task has me utterly bored, so let me tell you about the crazy things I’m thinking about while refinishing the furniture.

I’m going to stop and jump to step 5 (oh, heck, if inspiration strikes, I may even do step 4). It isn’t as if refinishing the furniture is any stupendously mysterious process. It’s the same darn process everyone uses with Fornby’s (rub in the stuff with steel wool, following the grain until its clean).. Here are the tips I have learned—wear a sealed respirator, lots of protective clothing and wield a big fan. Crank up NPR and get working!

Meanwhile, Rick removed more of the doodads on the hitch. He got everything off except the coupler, which will probably be an epic adventure.

Mandatory Work Break!

It’s exceptionally nice when a messy job requires taking a break! Today is fume day—I’ve set up a big fan in the trailer (mostly for ventilation purposes), strapped on my respirator (outfitted with new filters) and I’m doing the solvent dance! Presently, I have a half hour break while the adhesive remover gets working. Because of the fire danger (this stuff can spontaneously combust), I’m dividing my work into two sections, so that will mean two breaks. Then I get to work with the really nasty stuff—Fornby’s refinisher. Goal: Get all the woodwork cleaned and refinished today. It sounds like a big order, but I am excluding the cabinetry we removed, the panels I intend to replace—plus, it’s pretty easy when I don’t have to worry about drips!

I am not quite certain how to remove the doors from the overhead compartments. They are a bit complicated, but I’m sure once I get my head up into them, I’ll figure it out.

Yesterday, I bounced between working on the trailer and going to a Toastmaster’s convention. I’ve been a Toastmaster (a group that helps adults learn public speaking and leadership skills) for the past three years and as it turns out, the convention for all the clubs from Virginia up to Canada occurred three miles from my house. So, I changed clothes three times over the day and bumped off to various sessions! One minute might find me scrubbing aluminum, but a half hour later, I’d be sitting in a session dealing with, say, the finer points of motivating volunteers!

Friday I made it out to my local powdercoat specialist. It wasn’t exactly what I expected, this operation was HUGE! They do everything from small motorcycle parts to battleship hulls! Still, I can’t say how nice these folks are. The owner came out, looked at my range and told me that he couldn’t safely coat the stovetop. Now, I know other folks have had this done, but he explained to me that really, the paint is only good to 400 degrees and that even the high temperature paint would not stand the heat of a gas burner. He suggested going to an enameller, but indicated that he didn’t know of one, and that the fellow who used to do it locally closed shop. Anyone know of a decent enameller near Virginia?

Afterwards, I headed off to the local trailer parts shop, to pick up parts for overhauling the hitch. We plan to add in a new spare tire holder, move the propane bottles and possibly replace the coupler.

Earlier in the week, we had a fun time cutting off the old bottle rack—I had my first experience with a sawzall. I’d been rather afraid of them, but Rick persuaded me to give it a try. Once I got started up, I had a great time cutting—why the heck was I afraid of this? My fear was utterly irrational (considering I’m not afraid of other saws). It wasn’t even hard to handle. Anyways, we ended up joking around afterwards and celebrated frosty cold cokes on a warm summers evening…

Monday, June 06, 2005

Neatening Loose Ends

Meanwhile, reinserting the window went smoothly. I cut away the bottom (not showing) part of the gasket in the corner, filling the gap with Parbond caulking. The result is fairly acceptable, as shown in the photo below.

The frame is pretty much done, except for one side (not showing). I ran out of gasket and I'm waiting for Airstream Dreams to send me more to do that last edge and one final window.

After finishing with this, I spent time organizing tools and cleaning up the trailer. Looking at the whole situation, I realized I didn't want to deal with refinishing the woodwork, so I took on a different project, cleaning the stove. It's actually indoors now, since we took it out of the trailer. I was amazed at the layers of crud covering it. Right now, the outside surfaces are clean, but the inside still has more grease than I'd like under the cooktop (though I tried to clean that, too). Right now, I'm hoping to get this powdercoated--it would allow me to change it to a bright turquoise (look at my interior shot here and tell me it wouldn't look great) and as a bonus, would cover the chips in the enamel (not really visible in this photo). But the local powdercoater isn't sure he can paint this one, so I'm going to bring it by his shop Friday for the verdict.

Sunday, June 05, 2005

Window Epic Resolved...

This weekend, I only have today available for working on the trailer, so it's a busy day. Rick finished installing a fantastic fan, I installed windows. We planned to try to re-seal our skylight, covering the cracks with a layer of epoxy. However, when Rick removed it, we quickly realized that what we have is a bad replacement job. The skylight is not original, it's not fiberglass, it's comprised of two badly cracked pieces--and most critically, it doesn't appear to fit correctly. So, plan to put it back up and send off for a new reproduction skylight from Airstream Dreams.

Yesterday, before getting to my main task of the day (painting), we headed out early to the lumberyard and on a supply run. We made our first ever trip to Harborfreight Tools and bought a bunch of specialized power tools--their prices are exceptionally inexpensive, so we were both happy with our respective purchases. In our minds, so long as these tools last through this job, we figure its worth paying 75% less.

Well, since I don't have to worry about refinishing the skylight, I'm going to get a little more time in refinishing woodwork. It's a very nice day out, so it's a good time to do it.

Thursday, June 02, 2005

Window Epic, Part II

You see, a cautionary tale hangs there. Late last week, I started readying the window that I had "alumiwelded"--and noticed that the joint was moving. Before I knew it, one side had broken off. Cussing, I pulled out my torch and started to heat the frame to reapply the solder. However, before the alumiweld soldier stick melted, I noticed the frame started to melt. I stopped quickly, before it completely dissolved. I called around to parts shops--but it seems that the window frame is irreplaceable. I was advised that if the damage was small, it could be coaxed to workable condition.

Not knowing quite what to do, I took it with me when I made my second attempt to get to Blaine Window Hardware in Silver Spring. Apparently, the Blaine family had sold the shop off to one of their staff. A very kind Caribbean man served me.

Unfortunately, he could not match the window operators from his own stock, but he assisted me for an hour, giving me advice on fixing the windows and on repairing the melted frame (they could not do aluminum repair, unfortunately)--all this in exchange for a somewhat overpriced tube of Vulkem. I didn't get what I hoped for, but the trip appeared to be worth the effort.

So, on Sunday, I spent three hours drilling, auguring and grinding the frame into the profile that the window. After I finished, the melted portion of the frame looked identical to the undamaged part. Tuesday Rick took the frame to a TIG welder with precise instructions for the repair, based on the advice I got from the window repair shop. He was assured that they would do the work extremely carefully and according to directions--and that it would cost about $35.

Needless to say, the welder completely ignored my precise instructions and Rick got a $70 bill.

Results: The frame channel is completely filled with aluminum, so much so that there is no place for the glass to sit (I can fix that). The exterior profile has been destroyed (I think I can fix that). One side of the frame is 3/16" shorter than it was before (I cannot fix that).

It's been raining since then--I don't know if I can remount this window frame to the trailer, much less if the window will leak by consequence. If I can just get it to mount correctly, then I think I can maybe compensate for the missing 3/16" with a bit of creative gasketry and pass the leak test.

If it won't mount, our options will be very difficult.

One option will be to try to find a replacement frame from a salvaged trailer. This will be our best, though most difficult solution, since it will be tough to find a parts trailer with the correct age and of size window frame available. We would also find a wrongly sized window frame and weld in replacement segments to the existing frame. Our last and worst alternative will be to take out the entire window frame assembly and replace it with a modern window.

Have I learned a lesson? Yes, the service vendors in this area STINK like rotted rat puke.

Wednesday, May 25, 2005

The Bathtub Back!

Yesterday, Rick picked up the bathtub from the restorer. As it turned out, when we started really looking at the tub carefully, the little gash I had restored on the tub surface was actually a big crack in the back. It was caused by the tub being installed with blocks of wood at one side to slant the tub so the lowest point was the drain hole. The problem with this set up was that there was no bottom support for the fiberglass in between the blocks and the low point--so it cracked, probably multiple times. It ended up being hard to find a fiberglass shop that would handle that repair. The shop did a good job with the crack repair, shot a very nice epoxy paint layer, but I am disapointed that they didn't sand beyond the repair area (I suppose all my sanding efforts were not in vain, it looks pretty good). Honestly, I still think I could have done a better job, had I owned the spray equipment and a dedicated painting space. Still, the tub looks much better than the average tub in a vintage unit. It looks especially lovely sitting in the middle of our living room!

We're in a spell of wet weather right now, which is causing holdups for most of the jobs I want to do now. My largest priority is to remove the rest of the windows to restore them in a bulk fashion. I finally figured out how to remove the glass relatively safely from the windows, but its a slow process, so I want to do a bunch at the same time to move things along. I also want to get out to the window repair shop, but that's something I'm going to have to work out with my boss.

Meanwhile, I am still trying to figure out what is causing the leak on the side of the trailer (over where the old fiberglass repair was). I replaced the window, it's nice and tight, but the bellypan slowly got wet again from the rain. The other thing that might be a leak at the fiberglass skylight filter near there. That may have problems, but I won't know until I get up on the roof, hopefully this weekend.

By the way, I have to add a disclaimer on an earlier posting, since members of my family are now giving my mother a tough time about washing my mouth out with soap. My grandmother Gigi did it! Mom was great--she sympathized with my sad plight, then asked me if the experience left me with any future flavor preferences for soap!

Saturday, May 21, 2005

Window Epic Part I

Note: emphasis should be placed on "attempt."

However, rain, bad traffic and a broken serpentine belt conspired against me. I ended up shored up on an offramp to the Capital Beltway, vainly flagging passing vehicles for assistance. Finally a fellow stopped and muttered something to me in a slavic language and thrust his cell phone towards me. He looked friendly, so I dialed #77. Some time later (there were lots of accidents out there) I got a tow. Liberated of $128, I got a ride to the garage and walked home. Thus my epic adventure withered to its anticlimatic end four and a half hours after my first efforts for setting out to Silver Spring.

And as for Blaine Window Repair? Turns out the tow truck driver is buds with the owner. "Tell him Larry sent you."

Thursday, May 19, 2005

Finally Getting the Hang of Alumiwelding

I first started by testing the product out on a scrap of bellypan aluminum that Rick removed during last weekend's welding effort. That's a very small piece (3" square, say) of very soft aluminum. It heated up with a regular propane torch fairly rapidly. When it got sufficiently hot, a little bit of the surface did wrinkle, possibly because, as soft aluminum, it probably has a lower melting point. But overall, the test went exceptionally smoothly. Boosted by that, I moved on to my broken window frame.

After about ten minutes of trying to heat the frame, I decided that regular propane wasn't doing the job, so I moved up to the MAPP gas. Then I had a tough time keeping the torch lit. About that time, Rick decided to check up on me. Bad timing. With typical Mars efficiency, he proferred his solution. However, he was hitting this on a frustrated Venutian who really didn't want advice, just caring support and encouragement. Problem was, he was right, darnitall!

So, I let it cool down and found some scrap wood blocks to lift up the frame slightly off the ground, allowing me to hold the gas tank down lower and stop the torch from self extinguishing. I started heating it up again. Then just as I started getting it hot, it warped, moving the broken part out of position. Argh!

I headed into the house, down to the basement and grabbed the first set of nails I could find. I muttering as I passed Rick. Rick bent down over his textbook, recognizing me in a barely rational state. I was on a mission.

After nailing the frame in place, I started heating up the frame again. Oddly, this time, everything went textbook. I got in a nice, flat soldier. Finally! Barely in time--it as pretty dark out by this time. I yelled for Rick and did a little happy dance around the trailer!

OK, some tips...

1. I got my alumiweld from Eastwood Company, who gave me excellent service (received it next day after ordering on standard shipping). They also sell a positioning compound, which turned out to be very useful for getting my (warped) frame to sit correctly. If you can, I'd say, buy that as well.

2. I used an old wooden board as my soldering surface. Given my druthers, I'd have preferred to use a fireproof surface like a piece of Homasote board (available from building supply places). Then I could have clamped it to a work table and soldered away without fear of burning the table up.

3. I think this is definitely something to work on outside. It is pretty darn flammable and probably off gassed (I don't know, I wore my respirator, just in case).

Monday, May 16, 2005

Project Record: Window Repair

Please note--these instructions only apply to 1961-1965 models. I based my approach on RJ Dial's directions.

Difficulty (Scale of 10 Drills): TBD

Materials Used:

Window Gasket (available from airstreamdreams.com)

Glazing Tape (available from airstreamdreams.com)

Carpet knife and fresh razors

Straight edged razor

Screwdriver

Pliers

Wire brushes (copper for exterior, steel for inside channel)

Plastic to cover windows

Window sealing tape (weather stripping dept of Home Depot)

Frost King X-treme Rubber Weatherseal (or other rubber D shaped gasket) (or "Bulb seal" from Airstream Dreams

3m Super Weatherstrip Adhesive (yellow) (available from airstreamdreams.com)

Small cutting board

Gasket or adhesive remover (I used Permatex Gasket remover, purchased from Advanced Auto Parts)

Part 1: Window Removal

1. Remove the hand cranks* (1), tilting the window out (1b) so that you can release the window from the sliding mechanisms(1a). Pop them out and set aside in a designated place. We find this easier when a second person holds the window out.

2. Unscrew the side screws holding the window drip channel down on one side (2). Bend the channel up, so the window will slide past it. There is a small screw in the center of the window(3). If you cannot unscrew it by hand, use a set of plyers to remove it (a screwdriver will not reach this screw).

3. Lift the window up to about 2/3 open. Steadily push it out of its channel, towards the direction where you bent the drip channel up (4). This will release the window.

4. Before working with the window, cover the window with plastic and tape. Home centers sell a weather resistant tape with weatherstripping supplies. This product is good, although do note that it will leave a little residue glue on your trailer (though it cleans up easily).

Taped up window

Part 2: Window Repair

Once you get the corner out, it is easy to pry the rest loose with a screw driver.

2. The toughest part for me is removing the glass from the glazing tape. Right now I'm experimenting with applying different kinds of adhesive/gasket removers to the crack where the glass meets the aluminum, in hopes that it will seep down and soften the glazing tape. Hopefully, this will work and you can gently pry the glass out of the frame using a carpet razor. So far, this has led us to broken glass. Fortunately, the windows from this era were made of generic glass and are easily replaced.

3. Clean out the old glazing tape using gasket remover (I found Permatex gasket remover worked best). Scrub this channel clean (I used a wire brush), as it is your primary waterproof seal area. Optional--clean and polish the exterior of the frame (see earlier entry on this).

4. Roll out a strip of new glazing tape into the channel where the old glazing tape was. Trim it so there are no gaps. Carefully lower the glass pane back into the frame, setting it down on the glazing tape (I found this easiest with a helper, since there is no moving the glass again after you've set it down--that glazing tape really sticks to glass).

5. Use a flat edged razor and a small cutting board to mitre the starting edge of the new window gasket. Firmly pry it into the corner, making sure the lip gets wedged into the channel. Feed and pry it in place without stretching it. When you come close (say, 2 inches) to a corner, calculate where to cut it. I find it easiest to finish if I wedge it into the corner first, then work back to where I stopped to trim it.

6. Replace the window, reversing the procedures detailed previously. I am buying replacement operators, so I have not reinstalled these. I will post more info on this, when I do.

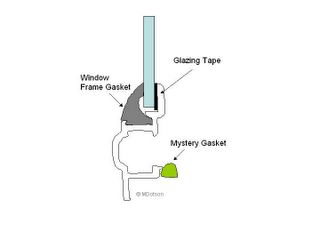

Part 3: The Mystery Gasket

I found a mystery gasket sealed the window inside the trailer wall. It is green in the window profile drawing above. You can also see a photo of it in the wall here.

This was stiff and cracked, so I decided to replace it as well. To do this, I bought "D" shaped gasket at Home Depot.

1. Remove the old gasket and clean the channel it sat in with window cleaner.

2. I found that the adhesive on the new gasket was inadequate. Instead, use 3m Super Weatherstrip Adhesive on the gasket, press it into place. Trim at the ends.

Since writing this, Airstream Dreams has solved the identity of the mystery gasket. It is called "bulb seal" and it will be available at their website starting 6/17/05. Unlike weatherstrip, it will not require adhesive. While I have completed all my windows with weatherseal, I am going to test out the new "bulb seal" one one window. My impression is that it will probably be a bit more durable than weatherstripping (which I expect will only be good for a year or two), though I don't know if it will give as tight a seal.

Welding and Still More Demolition

What a weekend!

Saturday started off early. Stuart Natoff came over to weld the front of our frame. He fabricated a beautiful replacement segment, then welded it right in. Turns out, Rick didn't have to recut the damaged part flush with the frame, but the new piece was so well made, it slotted in there easily. Due to the access to the belly pan, we were able to weld it from both the inside and the exterior sides. Afterwards, Stuart connected it to the skin with a couple of clecos (a kind of temporary rivet, which allows you to position things). The result was absolutely amazing. Previously, our trailer would lurch on its frame whenever anyone stepped onto the entry step. That has stopped. The whole trailer finally has a very solid feel.

Welding the front end

Result: nice new front end support

Now it may be a deep phobia, but I just cannot tolerate rodent droppings. Rick finds this a bit absurd, but it makes me start to think of hantavirus, the black plague and lots of other deadly diseases. It didn't matter to me that the sky was going nuts outside and the wind was pummelling the trailer. I pulled on my respirator and rubber gloves and got sweeping! I finished with a final spray of cleanser. Ew, ew, ew!

More floor rot found, so we removed the galley (rodent droppings removed)

Once we swept away the floor, the problem under the counter became clearer. Early on, we noticed that the trailer's water inlet leaked, so we've been traveling with bottled water. Now we can see that this had existed as a longer term problem than we'd imagined. I cut a small patch out of the floor. This revealed that in fact the decay is only created a slight disturbance to the top of the wood--but we discussed it and agreed that since the counter is gone and the space is open, we're going to replace it anyways.

So, with that in mind, we got to work on cutting out the rest of the front right flooring section for replacement. Earlier in the week, we'd cut off the bolts connecting to the frame out of the U channels (with a Dremel). Now we started cutting the rest of the wood out, taking turns with a circular saw set to 4/5ths of the plywood depth, then finishing with a jigsaw and a chisel. It all came out pretty easily. Finally we saw the full extent of the old fiberglass repair. Turns out the wood there was rotted all the way through, the repair consisted of a chunk of wood glued in with reinforcement cloth and epoxy. The result was pretty strong, actually, except it created a lump in the floor and they failed to repair all the rot (which appeared to be progressing). One piece of wood was less than a quarter inch thick with a thin layer of epoxy coating!

The weather turned nice, so I finished my efforts by finishing up cleaning out the window frame that had been fully slathered in silicone. Airstream Life Magazine's Rich Luhr had emailed me earlier in the week suggesting I try using a different adhesive remover, so I switched to Kleenstrip Adhesive Remover. This worked pretty well. It got most of the big bits out in quick order, but the tenacious little scraps of silicone, especially those stuck in the corners, still resisted removal. So, on went another layer of adhesive remover, followed after it set with brisk scrubbing with a steel brush and finally, picking out the crevices with a nail file. Ta da!

While waiting for the adhesive remover to work into the silicone, I started to play with two mini projects. I set up a ladder (padded with a towel against the trailer) and looked up on the top of the trailer. I failed to have confidence to climb up off the ladder (it's high and scary up there), however, I did get a good view of the top.

Then I tried to get in a test run with the Alumiweld sticks I got to repair the window frame metal (it cracked apart on one side). This is a kind of low-melt alloy of aluminum that can be melted on to repair aluminum and pot metal with just a propane torch. For my experiment, I pulled out some aluminum flashing sheeting that we had, decided to get artistic and cut out a bunch of aluminum leaves to fuse together. The Alumiweld instruction emphasized getting the base metal extremely hot before melting in the rods, so I grabbed a MAPP gas torch (a more purified kind of propane gas that burns hotter). I lit the torch up, set the flame low and lowered it onto my leaves to heat up the base metal. My pretty spring leaved withered into dry autumn form under the flame. This was so funny to me, I just burned up all the leaves to crumpled form, all the while humming the song "Autumn Leaves" (ok, ok, I admit I have a perverse sense of humor). Turns out, Home Depot flashing is cheaper aluminum than even Alumiweld! Well, I had to clean out the window frames at that point, so I'll give it another try tomorrow, maybe with a cooler burning propane than MAPP gas.

Tuesday, May 10, 2005

Silicone

I decided to take on the trailer’s rear window after work last night. It’s that silicone encrusted window I photographed last week. Getting it out was fairly easy, since all the operators had separated from the window (nor, for that matter, do they appear to operate) and the screws attaching it were already loosened. I sprayed on a thick layer of gasket remover and started to take on the silicone.

The layer of silicone holding the glass into the frame ended up being moderately manageable to remove. It just took several (about 5) passes with a putty knife and two hits with gasket remover and it slowly eased out. To my surprise, I found that one end of the frame had separated and had been held in place with silicone. Distantly, I recall that the previous owner had mentioned when I picked up the trailer that they’d broken the window operators during their big trip in the trailer the previous winter. This window started telling a story of an epic road disaster, leading to frenzied efforts with silicone. I like these folks, but right now, this silicone is irritating me, getting in my hair and pretty much annoying me.

I moved on to cleaning out the segmented aluminum channels filled with silicone.

There is no way to describe the tedium of removing silicone from aluminum. It is slick, something like greased over pork gelatin (and need I write that I don’t eat meat). It resists constraint, even from a sharp edge like a razor. It brought out the fiercest cleaning effort on my part—I found myself exerting the kind of determined scrubbing effort I can only recall my grandmother making in my early childhood. I can’t try to write how many gouges I made in the frame in this effort, although I suppose if the gouges are inside the window frame channel, it won’t really matter, since nobody will ever see them. After two hours of frenzied scouring, dark started to fade in. All that work, and I had only proceeded through one side of the frame—and there were still little traces of silicone in the channel.

Right now, I’m wondering if it really matters if there are random traces of silicone left behind, so long as the channel the gasket mounts to is clear.

All of this has left me musing about cursing. Bear in mind, I come from a family where my 4 year old niece thinks that the word “stupid” is a dirty word. I was fairly naïve myself as a child, getting my mouth literally washed out by soap after uttering a word I had learned from reading a Sherlock Holmes book, “dastardly.” Generally, I find curse words to be occassionally necessary exclamations, though lacking in originality and style. But every once in a while, I find a project like this silicone effort spurs so much frustration that it inspires me to try to invent a truly novel utterance of vulgarity. Consider the whole genre of cowboy vulgarity—half wild exaggerations that use panache to compare bad circumstances to the bluer side of rural life. But I don’t live in a farm and there is little vulgar panache to be found in general office work (cleaning out this window frame is like getting a virus that only lets you see one pathetic ugly porn website). Nope, there’s no {insert wildly creative vulgarity here} creativity or flair there.

Sunday, May 08, 2005

Gorgeous Day to Work...and Not Work!

So, went to town on cleaning. Organized the tools, then started sweeping. I've decided that the hantapoopies identification was wrong, based on the copious number of acorns stored under the tub area. I think it was more like chipmunk poopies, which is nicer, since while they still can make me sick, I don't face the prospects of dying from exposure. Looks like a chipmunk (I don't think it was a squirrel, since our squirrels are too fat) may have fit into the bellypan, then ran up the p-trap hole into the trailer behind the tub. Makes me think we'll have to see about the joints in the belly pan. Finally finished by scrubbing out the tub and hosing off the toilet. It still has the yucky wax seal, but I'm not feeling the urge to go crazy with this quite yet.

Finally decided to go ahead and get a professional job done on the tub. It's not that I don't think I can finish it, but I do think a pro will be able to shoot a much nicer spray coat and get better results in a dust free spray room than I ever could. Rick agrees--we're going to look into this later this week.

After that, went to work on the windows. Finally got the first window completed, reinstalled, save for the operator. Turns out the company that sells the replacement operators has their store in close by in Silver Spring, MD! Pretty darn cool--so will try to get down there soon as well.

Getting the gasket in the window turned out to be rather slow work. It really jams in there, so it took about two hours to work it in with a putty knife and a screwdriver. But if slow, it was pretty easy. Finally it was done, got Rick to help me reinsert it. Then I used some regular D shaped weather stripping from Home Depot to replace the "mystery gasket." Unfortunately, though the stuff had adhesive, it really didn't stick, so I'm going to have to get some gasket adhesive to keep it in place. But overall, the window looks great.

Then I started thinking about doing another window, but momentum stopped for me. I installed new lenses on the taillights--managed to crack one by overtightening (it stays for a while, I'm afraid). I also played with installing a new locking deadbolt, but realized the old strikeplate was slightly too small for it. Considered taking it off and grinding it larger, but decided to take a nap instead. Woke up and decided to faux paint my gas tanks instead.

Painting the gas tanks was fun, little effort, cheap and rewarding. Now they look like brushed aluminum, instead of rusting off white! Yay!

Saturday, May 07, 2005

Vanity, crap and possession

No, it just continued to be a time sink, ending up in a stasis of varying levels of, well, revoltingness. Last weekend, I spent hours sanding the tub down to a reasonable smoothness--with my husband, Rick, shaking his head in puzzled amusement when I told him it was cursed, that it was inhabited by a demon, that it needed excorcism.

Tonight, I don't think Rick disagrees with my assessment, although I feel that its liberation from the trailer may have been spiritually cleansing, hopefully divorcing it from the miscellaneous poltergeists it has obviously aquired in its life.

Goal today--clear out the bathroom. We started with removing the top of the vanity (some mildly tricky screws) then moved on to removing the toilet.

That was fairly easy. Next came the vanity body. It also removed after a bit of convincing (some more odd screws)--and guess what--we found hantapoopies left behind (YUCK).

Then came the tub. First we removed all the rivets and removed the P trap.

Then we took out most of the gaucho frame to see if there were screws holding in the tub.

No dice.

Then we removed the sliding door and the door trim (requiring cutting out lots of eensy teensy finish nails). This revealed still more screws that were removed.

No movement.

Finally, Rick released the partition. This revealed that all screws had been removed. Only one thing was possible.

The tub was glued to the floor. Glued well, good and solidly (just like an Airstream)! Dagnabit all, Wally, why did they do this?

Rick spent another four hours sawing under the tub. Finally after a whole day effort on the bath, the tub released at 7:45 pm.

Underneath, we found two things: a very old fire extinguisher and a candle with a teeny little note exhorting Jesus and God to stop Karen from doing drugs. Now, we don't know who Karen was or is, but obviously, this tub has been beset with some powerfully bad ju-ju.

We felt that while we may have not released Karen, we did release the tub. I went off for beer, salsa, shrimp and steak (most for Rick, since he did the heavy work).

Who ever that said bathtubs can't be possessed? I just hope this is over with it, finally...

Project Record: Refinishing Window Frames

The wrong way is to use a Dremel polishing kit and a wire wheel to clear off the silver toned paint a previous owner felt enhanced the natural aluminum finish. This way can only lead to hours of frustration, gouges and rough patches in the frame, black polish all over the polisher, achey arms from working hours on the polish and a deep yearning for something stronger than wine to help you forget what a mess you've just made of the window frame.

The right way is pretty darn simple and even removes most traces of the stupid mess the wrong way made for you.

Difficulty: (scale of 10 drills):

Materials:

Medium and Fine grade steel wool

Bathroom cleaner (anyone will do, I used Tile X)

Aluminum polish (whatever you can get that is rated for polishing aluminum--I used Mother's Aluminum Polish)

Paper Shop Towels

Warning--this is a really messy project. Wear clothes you can machine wash. You may want to wear gloves, though I found that if scrubbed, the polish mess comes off the skin fairly easily.

1. Use orange paint remover to strip off any elements of the silver paint left on by a previous owner (optional, considerate previous owners may not have left you such a inheritance). Tease off remnants of paint with a nylon scrub brush (not wire!), rub down with paper towels, then rinse off all remnant of the orange goo with water. Let dry overnight.

2. Spray the surface in segments with bathroom cleaner and scour thoroughly with fine steel wool. If this fails to lift up surface oxidation (ie, the little spots), use medium steel wool and scour until the oxidation is satisfactorily removed. Rub off with paper shop towels.

3. Polish surface with aluminum polish (almost any kind will do, this isn't a plated surface like alclad). This is best if done by hand.

4. Buff off the remaining polish with a clean paper shop towel. When the towel surface gets black, move to a clean part of the towel.

I managed to make an easy task very onerous here. But heck, think of the calories I burned!

Sunday, May 01, 2005

Weekend work report

Saturday I woke up achey, but I downed a couple of naproxen, strapped on my respirator and safety glasses and headed to work. The time horizon for this effort is somewhat limited--when we attack the back of the trailer, we'll be removing the tub, so I want to refinish it before that time.

After several hours of fighting a bucking sander, I stood up and removed myself from the tub. Granted, it was a cold, wet, rainy day--but every muscle in my body was stiff and cramped. I felt miserable. Moreover, I was completely covered with epoxy dust. Quickly I jumped into a hot tub and scrubbed myself all over. When I got out, I was sorer still. After a couple more hours of pain, I gave in and downed a Celebrex and went to bed.

By morning, the Celebrex had kicked in. Today, Rick was going to help me for part of the day (he's studying for finals right now). First we went out to Home Depot for a new Dremel head, then had breakfast out. When we got back, I put my "dust clothes" on and went back to sanding the tub. I sanded it to smooth across most of the surface. My next step will be to put a new layer of epoxy, smooth sand, then finish off with the refinishing compound (Homax's Tough as Tile). I am also going to reinforce a mended crack from the back when I get it out. Right now, I think if the rest of my steps go well, the results will be better than the original tub. I have found several "OEM" drips and spatters--these will be gone now.

Meanwhile, Rick took over in grinding down the cuts I made to the frame last Wednesday. Earlier last week, he bought a new Rotozip tool. He was looking forward to getting to use it.

My next goal is to replace all the seals on the windows. While Rick worked on his grinding, I got to work on refinishing my first window. I worked by following the project mentioned on RJ Dial's webpage.

Window seals are in bad repair...

And one window doesn't even have a gasket (that's just a fat bead of silicone holding that window in)!

After five hours of messing with this window, I gave up, covered the empty window hole with plastic, stored my tools and took a shower. I headed out to a sale at Nordstroms and finally felt restored to girliness again. When I returned home I had acquired a new suit, a Pucci scarf and miscellaneous underthings. So, we spent the evening watching tv (Miss Marple, World at War on PBS) and I started polishing the window frame with my Dremel. I have only cleaned up one half of the frame. This is going to take some time and effort to finish, darnitall.

Thursday, April 28, 2005

New Frame Diagram

Project Record: Replace the Teardrop Lights

Materials used:

Screwdriver

2 Pairs needle nosed plyers (for fishing out wire)

Plastic scraper

A few electrical caps (blue, to replace damaged ones)

Spray cleaner/degreaser

Paper towels

Galvanized screws or Olympic rivets (#10 x 1/2" pan head slotted zinc, 3 per light)

Vulcem caulk and caulking gun

Replacement teardrop lights (available at airstream dreams)

Steps

From the looks of the wiring, it appears that the old Bargeman lights were from a much older stock supply than my 1961 trailer

3. Unscrew the old wiring, checking the cap to identify if it is clean and can be reused. Twist the wiring from the new light with the wiring from the trailer. Cover it with an electrical cap and screw it together tightly.

Remove the old cault and clean the aluminum surface

6. Reposition the lights on the trailer and replace the screws. Caulk will seep out and you will find gaps between the trailer and light. Some of the gaps can be minimized by pressing to bend the aluminum edges of the lights closer to the trailer. Wipe off the excess Vulkem and allow the remaining caulk to cure.

8. After the caulk fully cures, fill in the remaining gaps with more Vulcem (apparently, using a turkey basting syringe comes in handy here). Also, carefully remove the screws one by one (try not to disturb the seal), adding Vulkem to the hole before replacing each screw or applying an Olympic Rivet. FWIW, I plan to do this step next weekend.

Stand back, crack open a cold one and admire your work!

I found that the new lights do not completely fill in the profile of the old lights. This leaves a trace of rust on the trailer surface. Folks embarking on polish jobs may wish to incorporate light replacement into their polishing project, buffing out the rust and replacing lights as they go. For us, we are doing this to stop water leaks (and I did find that two lights leaked). We plan to clean up the rust later on when we take on polishing.

Wednesday, April 27, 2005

Up to My Own Mischief

Slept in late and headed down to Home Depot for a couple of last minute supplies. Spent a bit of time trying to find the local Zolatone dealer, but couldn't find it in the industrial park. So, got home, gathered up my tools and got cracking.

My first effort was to cut off the remaining rusted portion of the frame member on one side. I did it with my Dremel tool (yet another thing you can do with a Dremel!!!). It took a long time, got the motor a bit warm, wore out a cutting wheel, but I really liked the result. The cut was extremely clean--and the Dremel was much easier to control than I expected. However, Rick doesn't feel the cut was sufficiently flush enough, so I may have to try over again. Oh, well, I'll deal with that this weekend.

I also tried to clean up the rust left there, but it's a struggle. I can't get the wire wheel (on my drill) down there. I may be able to reach with the dremel's wire wheel, but I wanted to let the motor get completely cold first. So, I spent about a half hour with a wire brush, then gave up.

Then I turned my attention to the flooring. Now that we've started working on the front, we are wondering what is underneath all the rest of the floor. Once again, I pulled up the carpet to look at the tiles underneath. Then I removed all the tiles not held down by pieces of furniture. Most of the tiles pretty much popped off when I set the pry bar to them. Three and a half tiles were not so cooperative.

These tiles were apparently reapplied at a later date with lots of thick, sticky adhesive. These were murder to remove and took a heat gun, hammer and chisel. I had a hard time holding everything, especially with the rubber gloves that were necessary because of the adhesive. Sometimes the tiles melted before the adhesive. Finally after about 30 minutes effort, they came up...and I found a nasty lumpy epoxy and fibercloth repair! Yuck.

I also made one other unpleasant discovery...as I moved towards the back, I became aware that the subflooring had odors that you couldn't notice standing up. Bad news.

So, when the going gets tough, the tough return to Home Depot!

This time, I did find the Zolatone dealer on the way--and was informed nicely, but firmly that they didn't sell paint except to contractors. Phooey. I'm not sure I'm taking that so easily...I'm the daughter of a builder and my Daddy taught me that there is one golden rule in the trade whenever you reach an impasse: get creative!

Continued on to Home Depot, got a handful of supplies, stopped for sushi, meditated on entering the contracting business, rolled my eyes and went home.

My last project of the day was replacing the teardrop lights on the trailer. This was an awesome project--one I highly recommend, since it takes little in the way of tools, requires little skill, but the results are fantastic.

Overall, I feel I used today productively, but can't stop wondering how much more we're still needing to do with this floor.